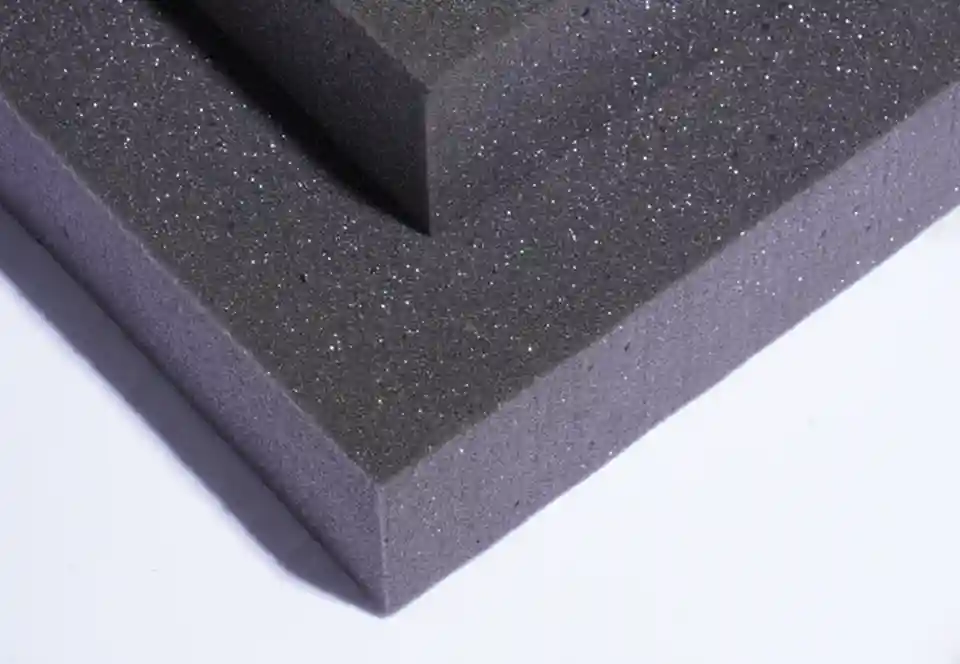

Polyurethane Foam

Polyurethane foam is also called flexible polyurethane foam and is a type of polymer created by a chemical process. The process involves a reaction of polyols and isocyanates, which gives PU foams a cellular structure. Its unique characteristics make polyurethane foams valuable for several products like mattresses, soundproofing, filtration, and more.

| Product Specification | ||

|---|---|---|

| Product Code | --- | |

| Density Available | 18, 24, 28, 32, 40, 45 & 50 Density | |

| Shape | --- | |

| Application | Automobiles,DG Industries, Packing, Sound Insulations etc. | |

| Patern | Square, Convoluted, Pyramid And Customised | |

| Sample Available | 1 no's | |

| Certification | ARAI & ISO | |

| Main Demestic Market | All India | |

| Colour | Gray, Black, White, Pink And Yellow | |

| Grades | FR and Non FR Grade | |

| Third Party Confirmation | ARAI for UL94 | |

Product Description

Polyurethane foams are created by the foaming process where two reactions happen simultaneously. One is the reaction between isocyanate and polyol (gelation), which forms the polymer network. The other is the reaction between isocyanate and water (blowing), producing the foam. The amine catalyst aids in accelerating the second reaction, thus giving PU foam mattresses their unique properties.

PU Foam Characteristics

Polyurethane foams are created by the foaming process where two reactions happen simultaneously. One is the reaction between isocyanate and polyol (gelation), which forms the polymer network. The other is the reaction between isocyanate and water (blowing), producing the foam. The amine catalyst aids in accelerating the second reaction, thus giving PU foam mattresses their unique properties.

Here are some of the PU foam characteristics:

Wide Range of Hardness: PU foam can be produced to a wide range of hardness, allowing PU foam manufacturers to customize products as required. High Load Bearing Capacity: Apart from being versatile, polyurethane foam also has a high load-bearing capacity. This includes both tension and compression. For instance, a PU foam mattress can change shape under a heavy load but will return to its original shape and structure when the load is removed.

Tear Resistant: One of the most outstanding features of polyurethane is its high tensile property. This makes it very difficult to tear PU foam sheets or PU foam mattresses.

Resistant to Mold, Mildew, and Fungi: We often worry about hygiene while picking out upholstery or mattresses. Luckily, poly urethane foams don’t support fungal, mold, or mildew growth. This makes the material ideal for tropical climates as well.

Flexibility: PU foams are very flexible, allowing PU foam manufacturers to tap into their elongation and recovery properties. As flexible materials, poly urethane foams perform very well even in high- flex applications.

PU Foam Appcliations

PU foam manufacturers in India have tapped into their full potential to bring out a wide range of possible applications. For one, the polyurethane’s mechanical properties can be isolated. It can also be manipulated through creative chemistry to create solutions to several requirements. This also makes PU foams unmatched by any other material in the market.

One should also note that PU foams are available in two kinds – one is flexible and the other is rigid. The flexible polyurethane sheets are widely used upholstery fabrics for both domestic and commercial furniture. This includes PU foam mattresses, PU foam sheets in furniture like sofas, and so on.

On the other hand, rigid PU foam sheets are used in refrigerators, freezers, plastic sheets, and so on. Apart from PU foam mattresses, polyurethane foams are also used for filling voids. Polyurethane foams also have increased adhesive properties, making them ideal for use in building and construction. More importantly, PU foams are used as insulation, including sound, heat, and water insulation.

PU foam sheets are also used in packaging, textiles, fibres, and apparel. Additionally, poly urethane foam is also used in appliances, machinery, electronics, footwear, and even transportation like automobiles. From this, one can conclude that PU foam sheets are highly versatile, easily available, and very affordable

FAQ's

Polyurethane foam is a versatile and widely used foam material created by mixing polyols and diisocyanates. It can be found in various forms, such as flexible foam (used in cushions and mattresses) and rigid foam (used in insulation and construction).

Polyurethane foam is known for its excellent insulation properties, durability, resilience, and versatility. It can be customized to exhibit a wide range of properties, from soft and flexible to rigid and dense.

Polyurethane foam is used in a variety of applications, including furniture and upholstery, automotive interiors, construction insulation, packaging, and even in the aerospace industry for its lightweight and insulating properties.

In construction, polyurethane foam is used as insulation material to create a thermal barrier. It reduces heat transfer through walls, roofs, and foundations, resulting in improved energy efficiency and reduced heating and cooling costs.

Yes, polyurethane foam can be customized in terms of density, firmness, size, shape, and other properties to meet specific application requirements. This versatility makes it a preferred choice in various industries.