XLPE Foam Plane Sheet

XLPE foam is a closed-cell foam material with cross-linked polyethylene as the base polymer. It has excellent physical properties, including flexibility, durability, and shock absorption. It is lightweight, waterproof, and offers excellent thermal insulation properties. XLPE foam plane sheets are highly versatile and can be used in various applications, thanks to their numerous beneficial characteristics. One of the most notable characteristics of XLPE foam plane sheets is their ability to cushion and absorb shock. This makes them ideal for use in packaging materials, as they protect fragile products during transportation. The sheets can be easily cut and shaped to fit specific products, providing a secure and snug fit that prevents any movement or damage.

| Product Specification | ||

|---|---|---|

| Product Code | SF908 | |

| Density Available | 70D, 85D, 110D, 165D | |

| Description | Re Bonded Chipped Polyurethane Foam | |

| Application | Used as Mats in Clean Room Applications, Automobile Industry, Auditoriums, Packaging Industry, Mattresses & etc. | |

| Third Party Confirmation | N.A. | |

| Note | Detail Technical Report Available on Request | |

Product Description

XLPE foam plane sheets are also highly resistant to chemicals, oil, and grease, making them ideal for use in industrial applications. The foam can be easily cleaned and sanitized, making it suitable for use in food processing facilities. Additionally, the material is resistant to UV radiation, ensuring that it won't break down or deteriorate when exposed to sunlight.

Another beneficial characteristic of XLPE foam plane sheets is their thermal insulation properties. The closed-cell structure of the foam prevents heat from escaping, making it ideal for use in construction and HVAC applications. The foam can be used to insulate pipes, air ducts, and walls, reducing heat loss and lowering energy costs.

XLPE foam plane sheets are also highly durable and long-lasting. The material resists moisture and mold growth, ensuring that it won't break down or deteriorate over time. It is also resistant to tearing and puncturing, making it suitable for use in high-traffic areas where it may be subject to wear and tear.

XLPE Foam Plane Sheet Characteristics

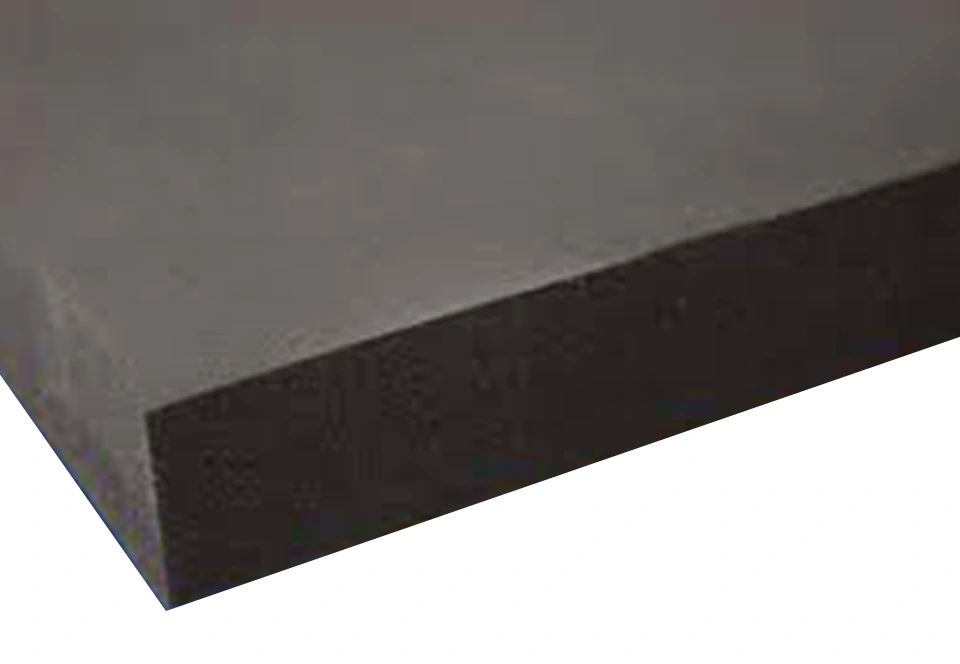

XLPE (cross-linked polyethylene) foam plane sheets are a type of closed-cell foam that is produced by cross-linking the polymer molecules during the manufacturing process. The cross-linking process gives XLPE foam a unique set of properties that make it ideal for a wide range of applications.

One of the key characteristics of XLPE foam plane sheets is their high strength-to-weight ratio. This makes them an excellent choice for applications where weight is a concern, such as in the construction of lightweight aircraft components, insulation panels, and protective packaging.

XLPE foam plane sheets are also highly resistant to water, chemicals, and UV radiation, which makes them an ideal material for outdoor applications. They are also able to maintain their physical properties over a wide range of temperatures, making them an excellent choice for use in extreme environments.

Another key characteristic of XLPE foam plane sheets is their ability to absorb shock and vibration. This makes them ideal for use in the manufacture of protective padding and cushioning materials for a wide range of applications, including sports equipment, automotive components, and medical devices.

XLPE foam plane sheets are also an excellent thermal insulator, which makes them an ideal choice for use in the construction of insulation panels and HVAC systems. They are also able to provide a high degree of sound insulation, which makes them an excellent choice for use in the manufacture of acoustic panels and soundproofing materials.

In addition to their physical properties, XLPE foam plane sheets are also highly versatile and can be easily cut, shaped, and formed to meet the specific requirements of each application. They can also be laminated with a wide range of materials, including fabrics, films, and foils, to provide additional functionality and performance.

Overall, XLPE foam plane sheets are an excellent choice for a wide range of applications where a combination of strength, durability, and versatility is required. Whether you are manufacturing protective padding, insulation panels, or soundproofing materials, XLPE foam plane sheets offer a unique set of properties that make them an excellent choice for a wide range of applications.

XLPE Foam Plane Sheet Applications

XLPE foam plane sheets are made from cross-linked polyethylene foam that is durable, lightweight, and has excellent insulating properties.

Here's more information on the applications of XLPE foam plane sheets.

Construction industry: XLPE foam plane sheets are used in the construction industry for insulation, roofing, and as a sound barrier.

Automotive industry: XLPE foam plane sheets are used in the automotive industry for noise and vibration dampening, as well as for insulation.

Packaging industry: XLPE foam plane sheets are used in the packaging industry for cushioning and protective packaging.

Sports industry: XLPE foam plane sheets are used in the sports industry for padding and cushioning in helmets, protective gear, and footwear.

Medical industry: XLPE foam plane sheets are used in the medical industry for orthotic and prosthetic devices, as well as for cushioning and support in medical equipment.

Marine industry: XLPE foam plane sheets are used in the marine industry for buoyancy, insulation, and sound dampening.

Aerospace industry: XLPE foam plane sheets are used in the aerospace industry for insulation, vibration dampening, and as a structural material.

Electrical industry: XLPE foam plane sheets are used in the electrical industry for insulation and as a dielectric material in electronic components.

Overall, XLPE foam plane sheets are versatile and have a wide range of applications across many industries.

FAQ's

XLPE foam plain sheets are sheets of Cross-Linked Polyethylene foam with a smooth, unaltered surface. They are used in various applications for their cushioning, insulation, and shock-absorbing properties.

XLPE foam plain sheets are commonly used in industries such as packaging, construction, automotive, and electronics. They are employed for applications requiring protective cushioning, sound insulation, and thermal insulation.

XLPE foam plain sheets are known for their excellent shock absorption, resistance to moisture and chemicals, low thermal conductivity, and versatility. They can be customized for specific applications

XLPE foam plain sheets have a low thermal conductivity, which means they are effective at reducing heat transfer. This property makes them valuable in applications where thermal insulation is required.

Yes, XLPE foam plain sheets can be customized in terms of size, thickness, and specific requirements to suit a variety of applications and industries. Manufacturers offer the flexibility to tailor these sheets to meet different needs.